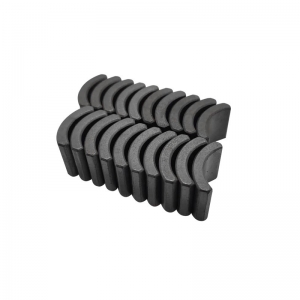

About Neodymium Magnet

NdFeB permanent magnetic material is an alloy of neodymium and iron oxide, which is widely used due to its excellent magnetic properties, and is known as the "king of magnets" in the magnet industry. NdFeB has a very high magnetic energy product and coercive force, at the same time, the advantages of high energy density, so that NdFeB permanent magnetic material in modern industry and electronic technology to obtain a wide range of applications.

Sintered NdFeB is the largest and most widely used product in the NdFeB family, which is produced by powder metallurgy method, and is divided into 7 series according to the different coercive force of the products: N, M, H, SH, UH, EH and TH. At present, the commercial production of sintered NdFeB, remanent magnetism up to 1.45T or more, endowed with the highest coercivity up to 2786kA/m, according to the different coercivity of the working temperature in the coercive force of 80 ° ~ 200 ° between. Sintered NdFeB is easy to be oxidized and corroded, so it is necessary to do surface treatment, according to the different requirements of the use of the environment, can be used phosphating, electroplating, chemical plating, electrophoresis, vapor deposition and other means of surface treatment, common plating, such as zinc, nickel, nickel-copper-nickel, epoxy resin and so on.

About Platings/Coatings:

Neodymium magnets are a composition of mostly Neodymium, Iron and Boron. If left exposed to the elements, the iron in the magnet will rust. To protect the magnet from corrosion and to strengthen the brittle magnet material, it is usually preferable for the magnet to be coated. There are a variety of options for coatings, but nickel is the most common and usually preferred. Our nickel plated magnets are actually triple plated with layers of nickel, copper, and nickel again. This triple coating makes our magnets much more durable than the more common single nickel plated magnets. Some other options for coating are zinc, tin, copper, epoxy, silver and gold.

Unlike gold, zinc and nickel, the epoxy magnet coating serves as an excellent barrier to salt, ambient air, water or moisture. However, it is slightly more expensive than the first three alternatives. Although it scratches easily and is 15-30 um thick, it has excellent adhesion to steel with magnetic adhesive. Epoxy coatings are mainly used in the marine, motor, sensor, automotive and consumer goods industries.

About AOMAG

AOMAG Magnetics is a leading permanent magnets manufacturer since 1996 in China. All our items are coming with certification and we have special team work for after sales service. We view quality as company's life.We can provide you with high quality products. Meanwhile,with our own factories, we are able to help you developing more technical products for your application.

If you are interested in our products, or if you have any questions, please feel free to contact me.