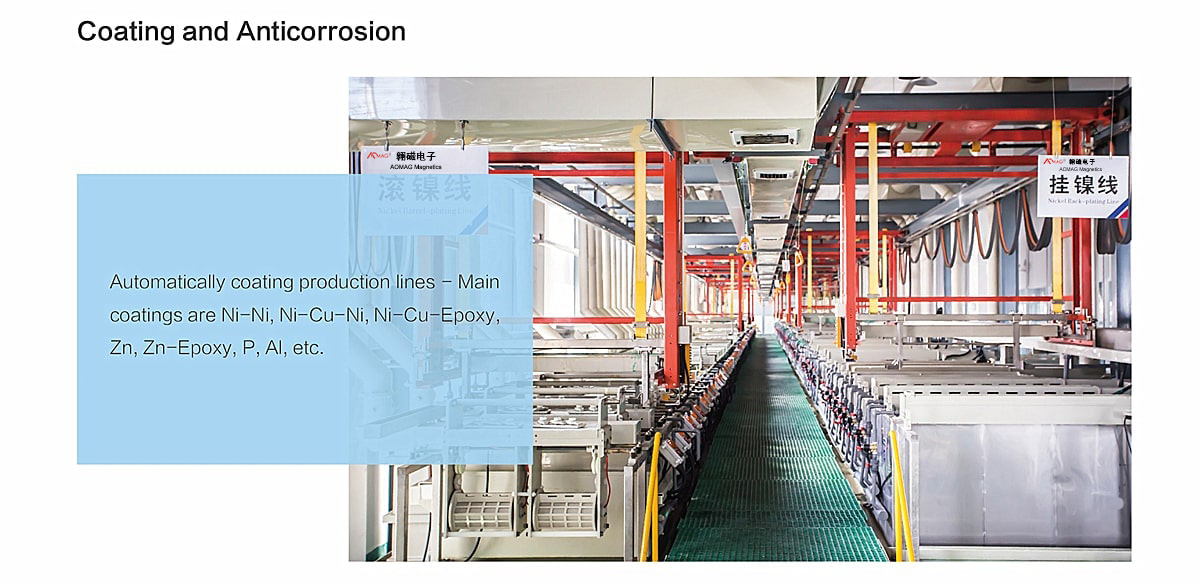

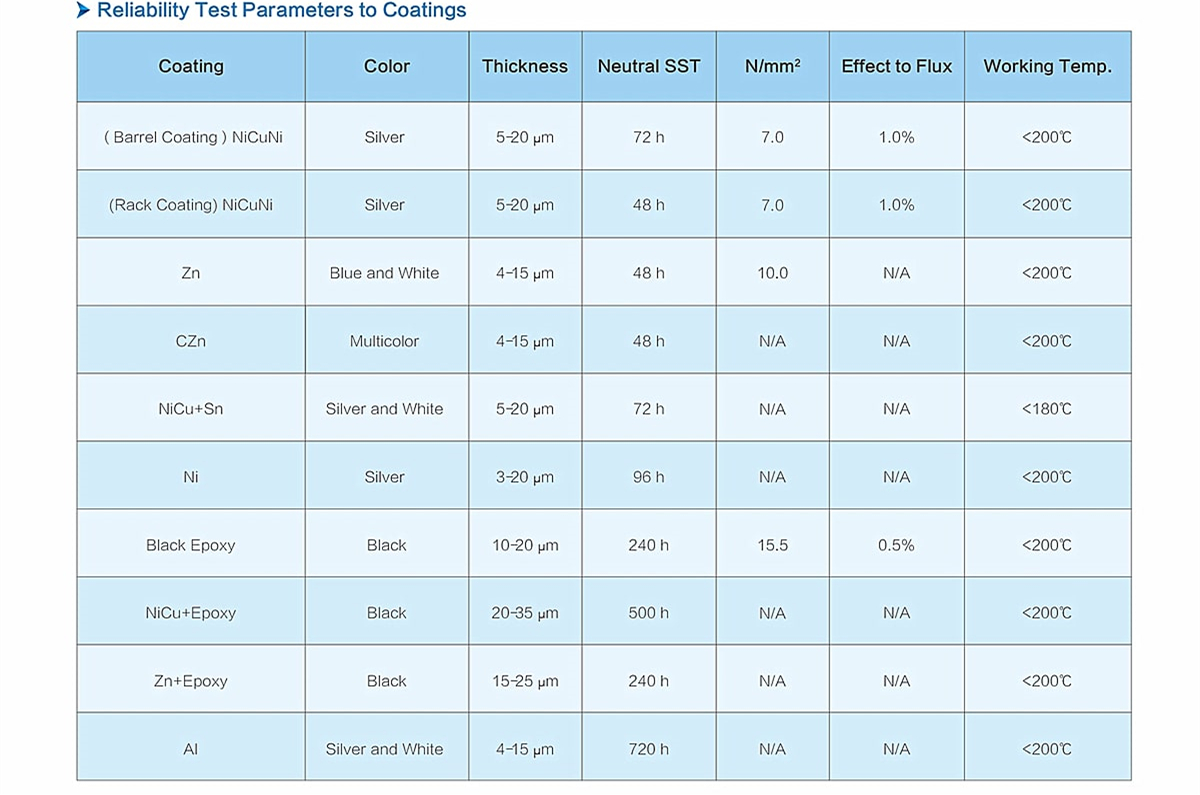

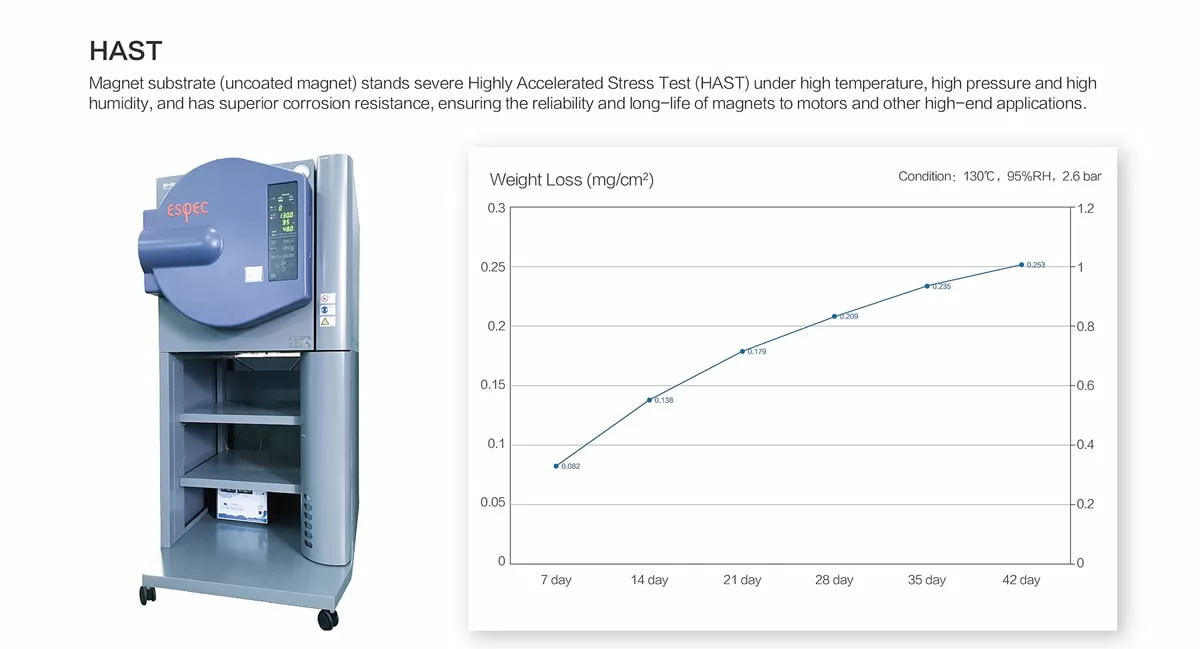

NdFeB material is easily oxidized when exposed to air, coating is necessary to protect it. We provide with all kinds of coating for magnets according to customer's applications. Even uncoated, our magnets have excellent corrosion resistance to assure super long life time. They perform superiorly in HAST tests under extremely high temperature, high pressure and high humidity conditions.Almost every neodymium magnet will be electroplated or coated. The main reason why magnets need surface treatment is to protect their surfaces from corrosion and damage, and to enhance their service life and performance. At present, the main coating technologies of magnets are: zinc plating, nickel plating, chromium plating, gold plating, silver plating, black nickel, epoxy and colored zinc,etc.

Surface treatment can also improve the adhesion and corrosion resistance of magnets. By choosing proper surface treatment methods, magnets can adapt to different working environments and application requirements. Therefore, surface treatment is very important for the stability, reliability and life of magnets.